The phenomenon of ‘wear’ is of great concern to orthopaedic surgeons carrying out knee and hip replacements. Whenever two surfaces move or rub relative to one another there is always a problem with the production of wear particles especially when one of the bearing surfaces is softer like for example, polyethylene, in the knee.

Most current femoral components in total knee replacements are made of cobalt chrome. Excellent results are currently being achieved with this material. However these implants can roughen over time when placed in the body. In the knee when the femoral component rubs over the plastic (polyethylene) insert, the plastic surface can start to wear out or break up. The rougher the femoral surface the worse the amount of wear. These plastic wear particles or ‘debris’ can be responsible for the failure of the whole knee replacement not only due to the thinning of the plastic insert itself but also due to the body’s reaction to the microscopic particles which can cause loosening and thinning of bone at the implant interface.

The fast-paced world has extended the total knee replacement to the younger generation as well. With sports injuries and other mishaps, the knee surgeries or the knee replacements have extended to the old and the young alike.

The choice of the type of knee replacement is contingent on several factors- age of the patient, the level of motion, the budget of the patient and the current state of the knee. Usually, an elderly patient who has less physical activity may not need a oxinium implant relative to the younger patient who has to be physically fit all the time.

With the use of cobalt-chromium alloys as the prosthesis for knee replacement, it came to light that the chromium gradually wears out, the surface gets rough and some lumps or debris started forming in the knee leading to quick wear out of the metal. The metal does not stay resilient to cyclical load and stress of daily routine.

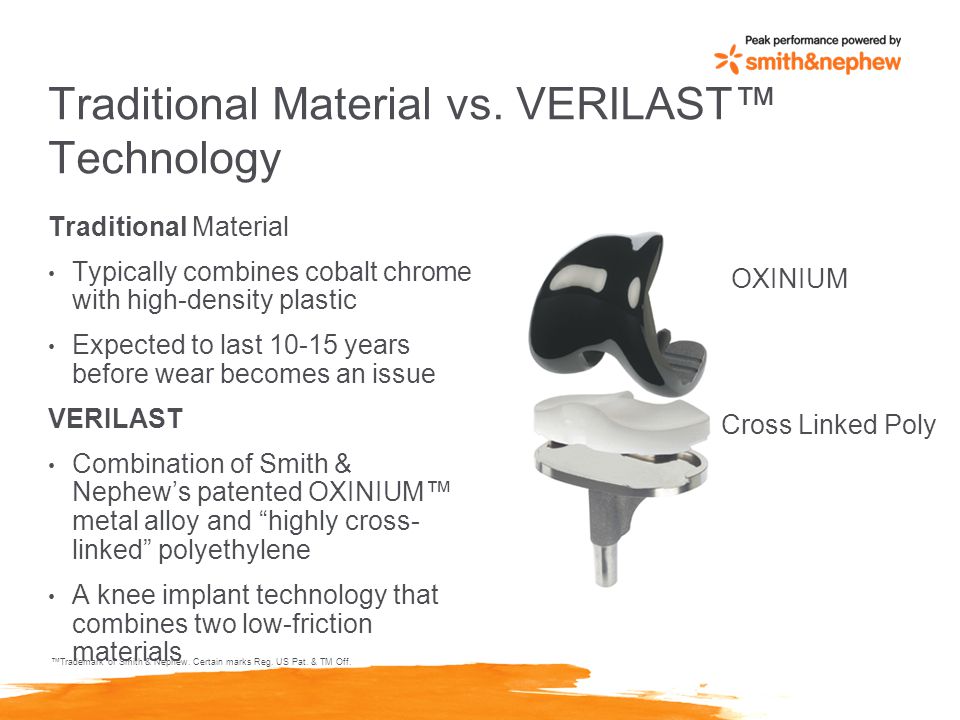

The risks of the knee replacement or the allergy to some patients due to metals like cobalt, chromium led to a phenomenal discovery of a new metal composition for the knee, femoral or the thigh bone area. The OXINIUM Oxidized Zirconium is a path-breaking, award-winning, and patented ceramic-metal alloy beneficial for younger patients who have an active lifestyle and a high level of physical activities.

Oxidized zirconium is the metal alloy comprising of 97.5% zirconium and 2.5% niobium. The resulting alloy is the most biocompatible metal known till date. The Oxinium has a ceramic-like surface and structure like metal.

During the process of manufacture of the alloy, the implant’s surface is made into a hard and ceramic metal with the body structure and durability of the metal inside. With the ceramic surface, the metal implant becomes twice as hard and twice as resistant to wear-out and abrasions compared to cobalt-chromium alloy.

There are various aspects which need to be considered in order to compare the two alloys of knee replacement:

The features of oxidized zirconium make it superior for femoral and knee replacement. the following people have highly benefited from Oxinium knee replacement

Total Knee Replacement should be a once-in-a-lifetime process if possible and this is possible if you use the best metal for the knee replacement.esp younger patients.

The contents of the website is not meant to replace an in- person consultation. Please follow the advice of your doctor via in-person consultation. This website will not assume any legal responsibility for the patient's medical condition.